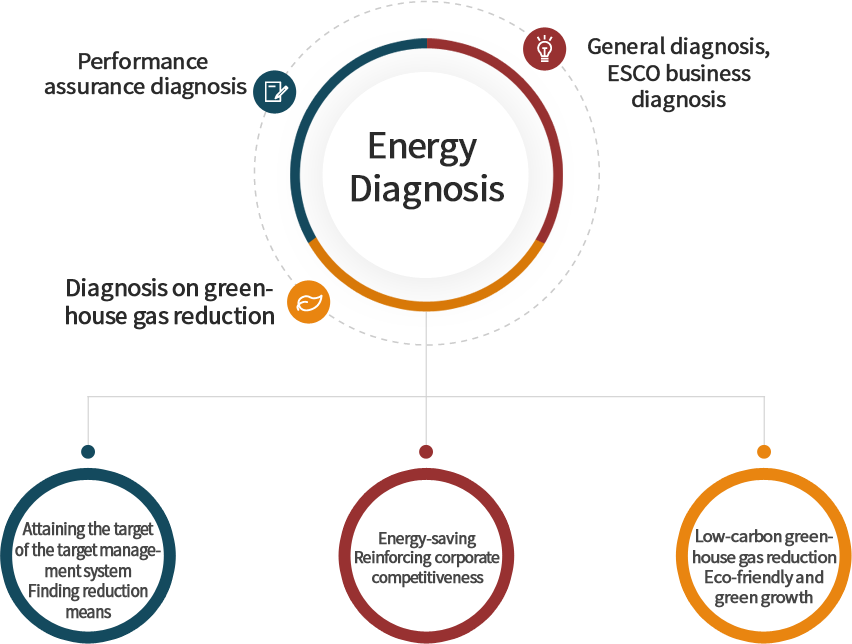

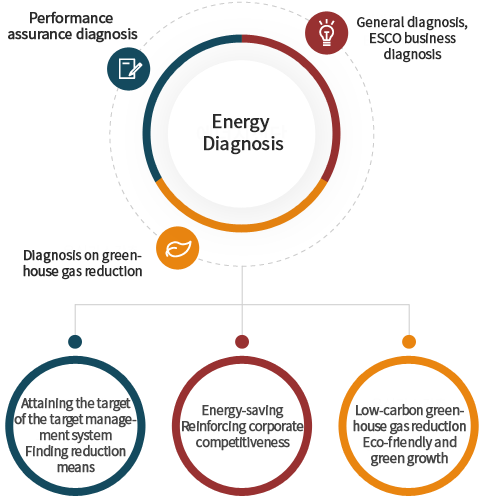

Consulting and Diagnosis Business

SP&G identifies the usage and loss factors of target energy facilities through its energy diagnosis business,

offering a technology consulting service that suggests economically feasible and reasonable ways to increase energy efficiencies.

offering a technology consulting service that suggests economically feasible and reasonable ways to increase energy efficiencies.

Diagnostic Effects

Management aspects

- Improved competitiveness of companies according to the reduced burden for energy costs

- Inspiration of company-wide mindset for saving energy

- Proposition of reasonable energy use models

- Reduced energy consumption rate through investment in reduction and motivation

Facility and technology aspects

- Prevention of energy loss through optimized facility operation

- Improved basic unit of energy and reduced environmental burden

- Stabilization of production and support facilities through the formation of optimized energy models

Diagnostic Procedure

-

01

Identification of energy usage status and process

- Preliminary diagnosis on consulting suitability and schedule negotiations

-

02

Selection of target facilities and processes

- Investigation of energy usage and facility data, interview with managers

-

03

Confirmation of usage through on-site diagnosis

- On-site measurements using diagnostic equipment, facility performance testing, and operation efficiency diagnosis

-

04

Discovery and analysis of energy waste factors

- Identification of energy losses, analysis of cause, and interview with hands-on energy managers

-

05

Preparation of improvement

measures - Review of improvement measures for each waste factor, economic analysis on facility investment

-

06

Guidance on

maintenance - Education on energy saving, explanation of consulting outcomes