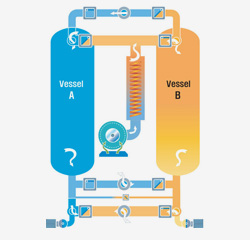

Non-purge Blower Type Adsorptive

Air Dryer

This product has a competitive edge compared to ordinary adsorptive air dryers with a high efficiency

and stable performance, recycling the air inside the vessel by sucking outside air through the blower.

Application Effects

Energy-saving

- Use of renewable air with a highly efficient blower -> Zero loss of purge air

- Increased economic feasibility from the use of a recycling blower

Reasonable maintenance

- No need for water filter and cooling water

- Single piping for compressors and dryers

Maintenance of stable dew point and provision of stable product performance

- Function to control within ±5°C when switching the vessel

- Function to select -73°C PDP for cryogenic dew point

Reduction Principle

PCM Phase Change Air Dryer

This air dryer has achieved astonishing energy reduction efficiency by only operating the freezing compressor when necessary by utilizingthe cold storage effect of latent heat and interlinking with compressed air load.

Application Effects

Phase change dryer

with differentiated technologies

- Application of a phase change material (PCM)

- Freezing compressor ON/OFF control according to compressed air load

- Reduction of energy use by up to 99%

Highest

efficiency

- Application of a stainless steel-brazed, plate type heat exchanger with built-in PCM

- Low energy costs -> Reduced by 99%

- Durable stainless steel

NO Loss

Drain

- Capacitance sensor

- Zero air loss when discharging condensate water

- Automatic switching to the timer mode when there is a problem

Oil removal efficiency

that is nearly oil-free

- Built-in cold coalescing filter

- Removal of 99.8% of oil

Reduction Principle