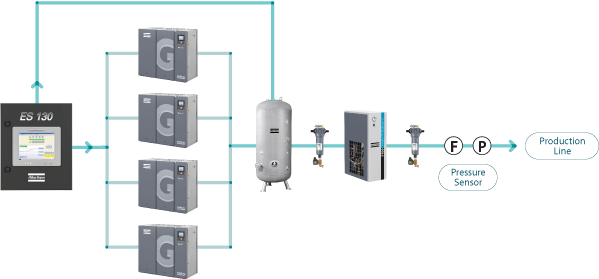

Integrated control System(Energy Saving System)

The integrated control system is a system that reduces energy costs and optimizes the efficiency of air compressors by operating,

stopping, and controlling air compressors under optimal conditions through real-time monitoring of required compressed air volume at plants.

stopping, and controlling air compressors under optimal conditions through real-time monitoring of required compressed air volume at plants.

Reducing energy costs is a crucial part of cost reduction.

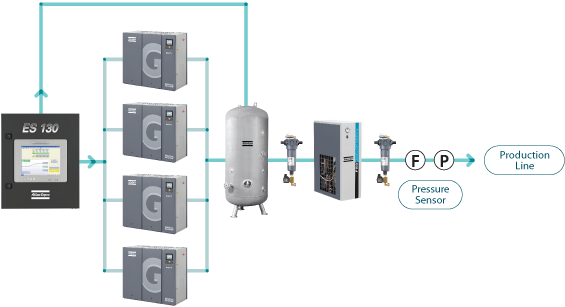

The integrated control system minimizes unnecessary

operation of compressors, maintains the best control, improves

processes,reduces energy costs, and lowers defect rates.

The integrated control system minimizes unnecessary

operation of compressors, maintains the best control, improves

processes,reduces energy costs, and lowers defect rates.

Application Effects

Planned maintenance

- Enabling planned maintenance using the automated sequential control function

Maximized energy reduction

- Maximizing energy reduction and reducing costs through integrated, remote control

Volume control

- Control of compressed air volume according to the required amount

Reduced power consumption

- Reducing power consumption by lowering operating pressure

- Automatic operation after restoring power after power failure

Remote, integrated control

- Remote, integrated control

of compressors - Automatic resumption of compressors after waiting when there is a problem during operation

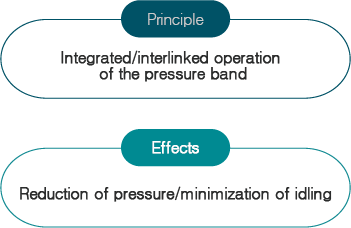

Reduction Principle

After building the integrated control system, we test and simulate the system for about two weeks at your company.

All histories, including pressure, flow, and compressed air use patterns, will be saved automatically. Your company can operate/control air compressors under optimal conditions.